Imagine that before you run a single board through your reflow oven you can see that your process is already in spec., and ready for production, without first running a manual thermal profile! Otherwise how else do you know for sure that your oven and process are in spec.?

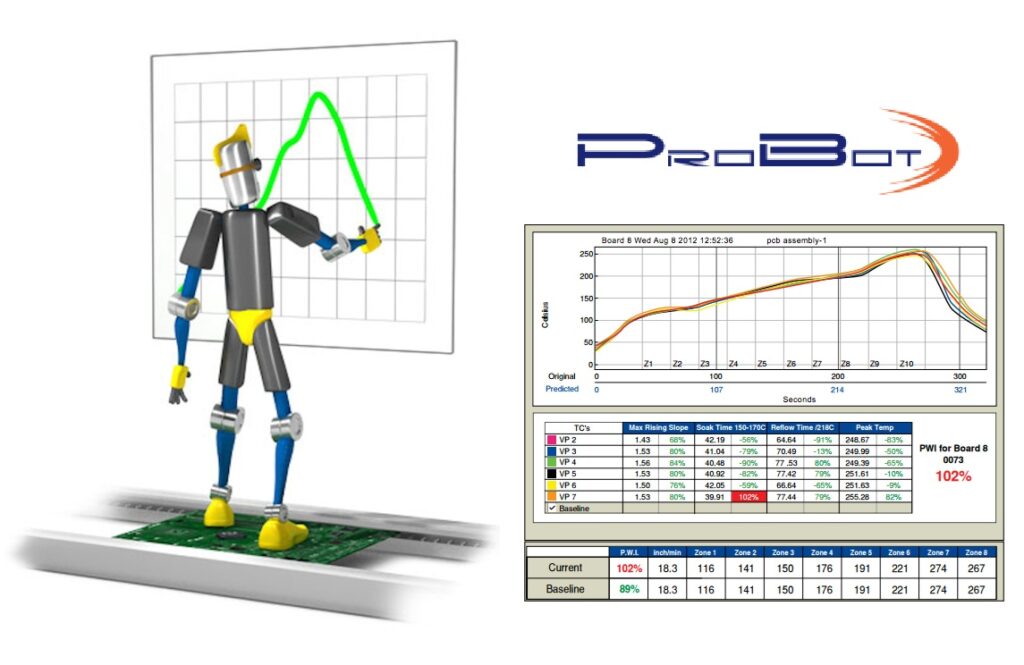

Automated Profiling with ProBot offers an always LIVE reflow profile, allowing the operator to see instantly that your reflow process is good (in-spec) before you allow boards to enter the oven.

ProBot software then monitors and automatically verifies whether each PCB is processed in spec., providing (automatically) a thermal profile for every board.

ProBot can automatically evidence your key reflow oven profile data for each customer.

Automated Profiling makes customer audits easier with automated profile data collection, a profile for every board, stored automatically & instantly accessible.

ProBot eliminates manual profiling checks, saving hours of process engineering and production time.

Ensure your reflow oven is always in-spec and get both live process data, and historical production data at your finger tips.

Complements AOI inspection by storing the relevant solder paste and component temperature tolerances and checking that each PCB was processed in accordance with these process windows.

When fitted with barcode and an Alarm Relay features can stop boards being produced with common production errors like “we ran the wrong oven recipe” first checking the barcode product ID against the oven recipe database as it arrives at the oven and then stopping the infeed conveyor if it doesn’t match.

Reflow Oven Set-up and process improvements can be quickly implemented with a KIC Smart Profiling System The KIC SPS Thermal Profiler is the fastest reflow oven set-up tool available, saving time whilst optimising your reflow oven.

Learn about KIC MAKING OVENS SMARTER

Further customisation allows users to automate the data and connectivity that’s important to your needs.

A list of just some enhanced features KIC ProBot offers:-

OPTIMISATION | |

|

Navigator Optimiser |

Automated solution for finding the correct recipe to put your process in spec for your product. Navigator gives you choices to customise the process for your factory requirements: highest quality, fastest production or both. |

|

Auto-Focus (includes Navigator) | Eliminates guessing on a new PCB’s recipe. Provides suggested recipe for an in-spec profile before running a board. Saves the cost of a PCB. |

|

Navigator Power Optimizer |

Navigator software plus an added energy savings optimizer |

| Auto-Focus with Navigator software plus an added energy savings optimizer | |

TRACEABILITY and CONTROL | |

| Barcode Reading Traceability | Automatically matches the barcode number with the completed profile data of every single production board recorded by the system. |

| Barcode Reading Process Control | Eliminate using the wrong recipe. Automatically compares the barcode of a product on the in-feed conveyor to a user defined barcode string for a particular profile recipe. |

| Barcode Reading – Traceability & Process Control | Package of Traceability and Process Control. |

| Lot ID | Production run data based on the Lot ID code. |

LOCAL & REMOTE VIEWING and TRANSFER | |

| RPM (Remote Process Monitoring) | The output of profiling data sent to the RPM Server Software at a separate location or externally to a flat file. |

| RPM Server One (1 seat license) | View profile data from the KIC server at a separate location. One (1) seat license |

| RPM Server Five, Ten, Unlimited (5, 10, unlimited seat license) | View profile data from the KIC server at a separate location. Multiple seat licenses. |

| LDO (Live Data Output) | Output of profiling data sent externally to a flat file. |

| Live Index Viewing | Screen displays a comprehensive summary of production quality assurance information. |

SPC and MAINTENANCE | |

| SPC/Cpk Charts | SPC/Cpk Charts – Statistical Process Control charts and Cpk calculation. |

| Troubleshooting | Tab display the probe and conveyor speed deviation to aid in determining potential problem area. |

Copyright 2012 – 2019 LINK HAMSON | All Rights Reserved | Powered by DIG Online