Rotating Viewer offers a new Angle on Inspection

Rotating Viewer offers a new Angle on Inspection Top down

Link Hamson have been supplying the UK electronics manufacturing industry for over 30 years. An innovative product range supporting both CEM and OEM electronics production activities, with our main products focussed on providing high quality equipment and consumables. Our extensive knowledge ensures you receive the best products and support.

With 26 years of ISO9001 accreditation, quality is our ethos and is reflected in our main product range.

With 26 years of ISO9001 accreditation, quality is our ethos and is reflected in our main product range.

Based in Newbury, Berkshire Link Hamson work with a range of innovative global partners to support the UK electronics manufacturing industry. Key equipment and consumables to support the manufacturing process such as the latest 4K Digital Microscopes for PCB, component Inspection and Metrology. High temperature polyimide labels & printing solutions for PCB identification & component marking. As a Weller Partner we are able to offer the full range of Weller Soldering and Fume Extraction Solutions. Reflow oven process control from KIC, the world technology leader of automating thermal profiling & management and Smart Profilers. Automated Rework & Dispensing solutions from MARTIN. We also offer a range of PCB assembly equipment, component storage and ESD furniture from Iteco and Treston.

Rotating Viewer offers a new Angle on Inspection Top down

U50s 4K 60fps PCB Inspection – For Highest Image Quality

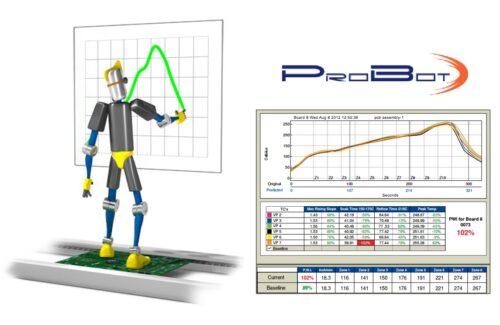

KIC ProBot – Starting your Automated Profiling Journey Let

HeatMap™ Real-Time Oven Monitoring Reimagined The latest real-time thermal process

Copyright 2012 – 2019 LINK HAMSON | All Rights Reserved | Powered by DIG Online