Machine Capability Analysis for Your SMT Reflow Oven using KIC SRA Smart Reflow Analyser

Identify and Track your SMT Reflow Oven Performance and Stability

Identify and Track your SMT Reflow Oven Performance and Stability

KIC Auto-Focus – Create New SMT Oven Recipes Without Running A Profile Auto-Focus Power is a ‘recipe search engine’ with an intelligent database, enabling the

Fast Smart Oven Recipes for SMT Reflow Do you spend hours of valuable engineering and production time creating thermal profiles for your reflow oven? For

Eliminating Reflow Oven Recipe Mistakes at Changeover How many times have you run production boards (PCBs) through your reflow oven on the wrong recipe? You

KIC Profiler Carrier Solution for Small Boards If you produce small boards you will know the challenge faced when profiling them, often the profiler and

KIC ProBot – Start your Automated Profiling Journey Let ProBot take the load and Eliminate your Manual Profile Verification KIC ProBot – The Automated Profiling

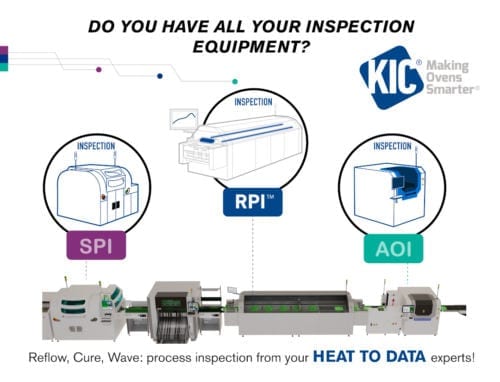

Reflow Process Inspection Need better defect analysis? Combine the reflow data with your SPI and AOI data for true defect data analytics. Without RPI you

Copyright 2012 – 2019 LINK HAMSON | All Rights Reserved | Powered by DIG Online