Do you spend hours of valuable engineering and production time creating thermal profiles for your reflow oven?

For new product introduction it is critical to ensure the reflow process is optimised for the solder paste and the PCB, both the board and components. But how do you modify your process, accounting for the needs of all 3 and your oven?

Thermal profiling is common place in SMT Reflow Oven processes, however the profiling process to get from the initial board to an acceptable reflow profile can take hours, multiple oven changes, each needing time for the oven to stabilise before a check profile can be run.

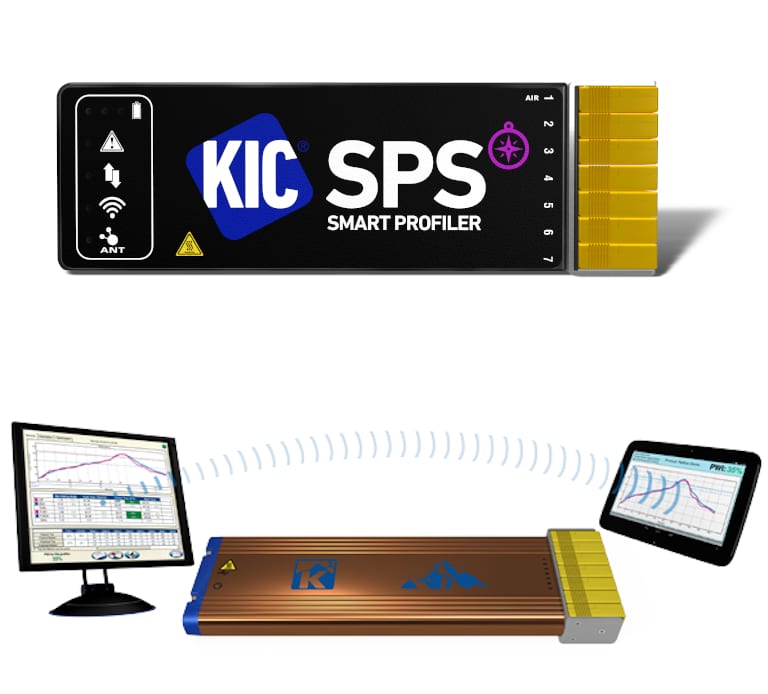

KICs SPS – Smart Profiling System can eliminate all the guesswork from this process. Simply select your solder paste from the inbuilt library, attach thermocouples to the key components and pass through the reflow oven. KIC’s Navigator software will measure the performance and automatically provide the new oven settings for you to use – and for many ovens* these changes can be written automatically to the oven software to avoid typo’s and miss-reads.

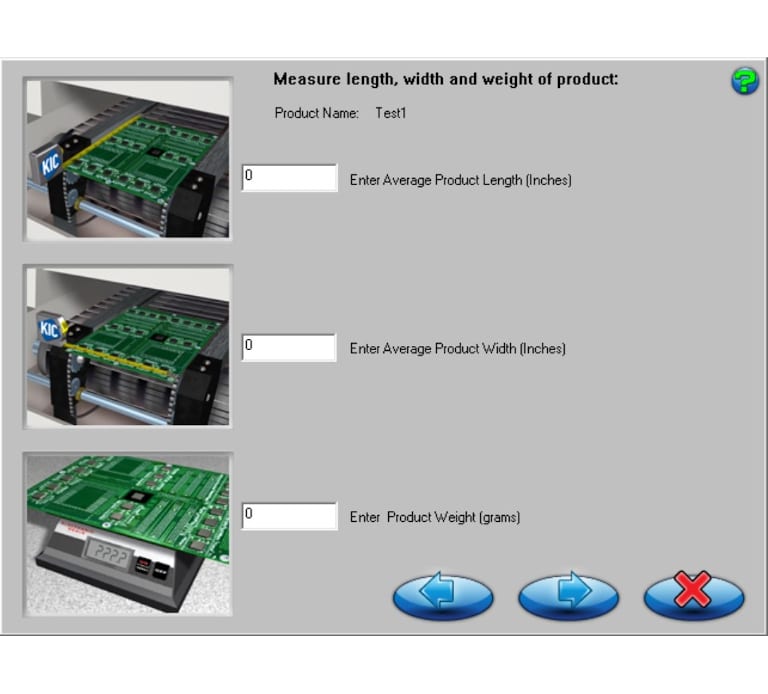

When used together with the optional Auto-Focus software for New Board Profile Prediction an existing user can simply enter the weight and dimensions of any new PCB and Auto-Focus will search your existing library of known good products for the nearest match. If that wasn’t easy enough KIC’s Navigator then runs to optimise the profile without even adding a thermocouple to the PCB.

If you would like to see how the KIC SPS (Smart Profiling System) can outsmart your existing profiler please contact us for a demo.

*Please provide details of the oven make, model and current software version and we will confirm if compatible with the recipe exchange feature.

Copyright 2012 – 2019 LINK HAMSON | All Rights Reserved | Powered by DIG Online