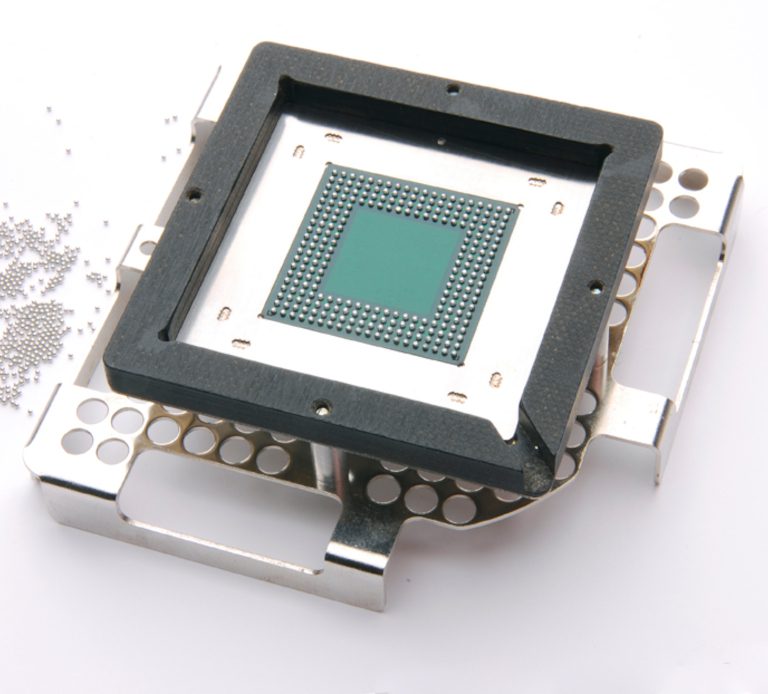

The Mini Oven 05 was developed originally to provide a fast, reliable and easy BGA reballing solution for rework applications, device failure analysis and forensics (collecting data from damaged electronic equipment such as a mobile phone by removing the memory devices, reballing them, and then re-assembling them in to a known working phone ), and also for third party repair centres.

However with the high cost of components, component shortages and incredibly long lead-times the Mini Oven 05 and BGA reballing tools are perfect for recovering and reballing used BGA devices for use with new products, or for legacy repairs where components can no longer be sourced. Removing the old BGAs from scrap or damaged boards using a BGA rework machine like the Expert10.6HV will allow them to be re-used in new products – effectively recycling your old BGAs!

With the current cost of devices the Mini Oven 05 can pay for itself over just a few components!

If you’re struggling to get the BGA devices you need in a Tin-Lead alloy, for exempt industries or for rework and repair of legacy equipment the Mini Oven 05 also offers a solution for component conversion.

Using a new lead-free device the lead-free solder balls can be easily removed and replaced with Sn/Pb (leaded) solder balls, converting the lead-free BGA component for use with lead solder applications.

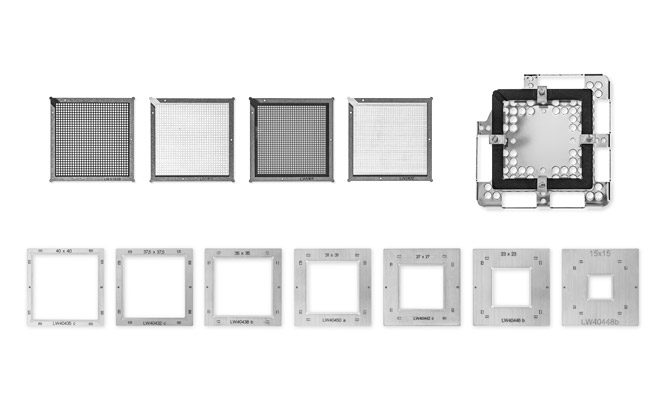

Reliable QFN rework is not easy to achieve; small, fine pitch, often relatively low cost devices the QFN creates a unique problem when using a traditional rework methods, either by hand (bumping or loading the pads with solder using a soldering iron) or when using a BGA rework machine with paste.

The ground plane in the middle causes the device to float higher than the outer pads as the solder volume is much greater than the smaller outer pads. To get repeatable results the volumes of solder need to be very precise. The Martin QFN pre-bumping solution for reworking QFN devices allows the user to precisely print the right amount of solder paste directly on to the QFN pads whilst it’s held in a mini-stencil-printer, then QFN Printer is placed in the Mini Oven 05 and reflowed so that it has solder bumps of the same height across the whole component…it can then be reworked similar to a BGA, using only flux.

Copyright 2012 – 2019 LINK HAMSON | All Rights Reserved | Powered by DIG Online