Rework

NEW Weller Solder Tip Cleaner Released

NEW Weller Solder Tip Cleaner Released – WATC100 Automated Solder Tip Cleaner Soldering iron tip cleaning has never been so easy. The NEW WATC100 Automatic

NEW Weller Solder Tip Cleaner Released – WATC100 Automated Solder Tip Cleaner Soldering iron tip cleaning has never been so easy. The NEW WATC100 Automatic

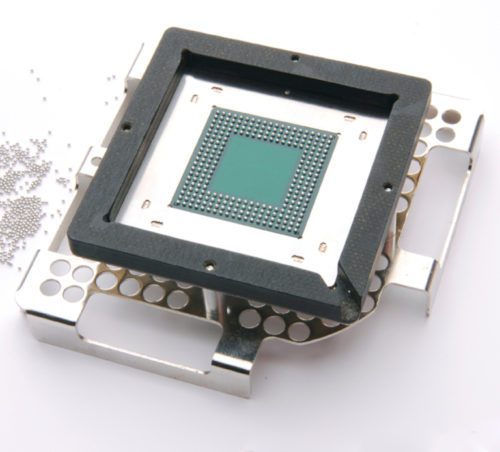

BGA Reballing Saves Money and Reduces Scrap The Mini Oven 05 was developed originally to provide a fast, reliable and easy BGA reballing solution for

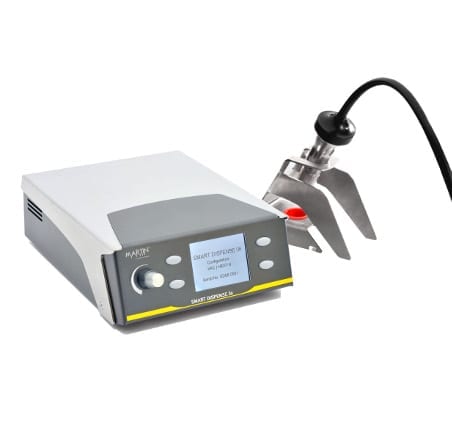

VIEW RELATED PRODUCTS The Martin Smart Dispense 06 allows for accurate and repeatable dispensing of fluids for rework such as solder paste or adhesives. The

Copyright 2012 – 2019 LINK HAMSON | All Rights Reserved | Powered by DIG Online