Why do I need to bake devices once the component floor life is exceeded?

Simply put moisture absorbed in MSD’s (Moisture Sensitive Devices) when thermally processed through an SMT Reflow Oven will boil, turn to steam and cause high internal pressures that can cause popcorning, cracking & delamination of the device layers internally.

The IPC/JEDEC standards around these are quite complex and you need to have controls in place to monitor the Floor Life (the time they have been exposed to ambient air). Once the Floor Life has been exceeded it will be necessary to bake these parts (times and temperatures according to the standard used) in order to remove the moisture safely and to reset the Floor Life on the component.

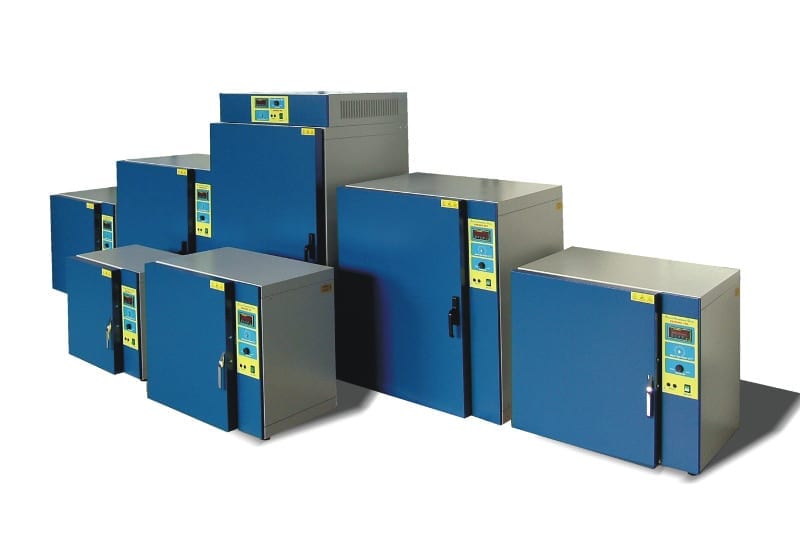

The Sahara Range of Forced Ventilation Ovens offer small desktop solutions for occasional use and large floor standing ovens for high volume continuous baking. These baking ovens were developed to safely process devices at both low temperature and high temperature bake programs, depending on the device or users needs.

For auditing purposes the PC software can log this process and record profiles for evidence of baking times and temperatures used.

If you intend to rework, repair or carry out any high temperature thermal processing on an assembled PCB you should consider the risk of trapped moisture in the components and PCB assembly. Subjecting the board to rapid heating can cause the moisture to create large pressures with the layers of the package, leading to delamination and popcorning.

The Sahara baking ovens can also be used to safely remove the moisture from the PCB assembly, prior to rework ensuring you don’t create additional failures & problems within the assembly.

To avoid issues with moisture sensitive devices (MSD) in electronics it is recommended to store these devices in a controlled environment like a Dry Storage Cabinet. This ensures that the components are stored in a controlled and monitored environment meaning the devices are always ready to be used immediately.

If you store components in a Dry Storage Cabinet there is no requirement to seal or repackage the parts, however if the components have been out of the cabinet for extended time they may need baking before they can be returned to the cabinet.

If you don’t have a dry storage cabinet you can repackage the components, once baked, in Dry Packaging, Moisture Barrier Bags (MBB), following the required standards.

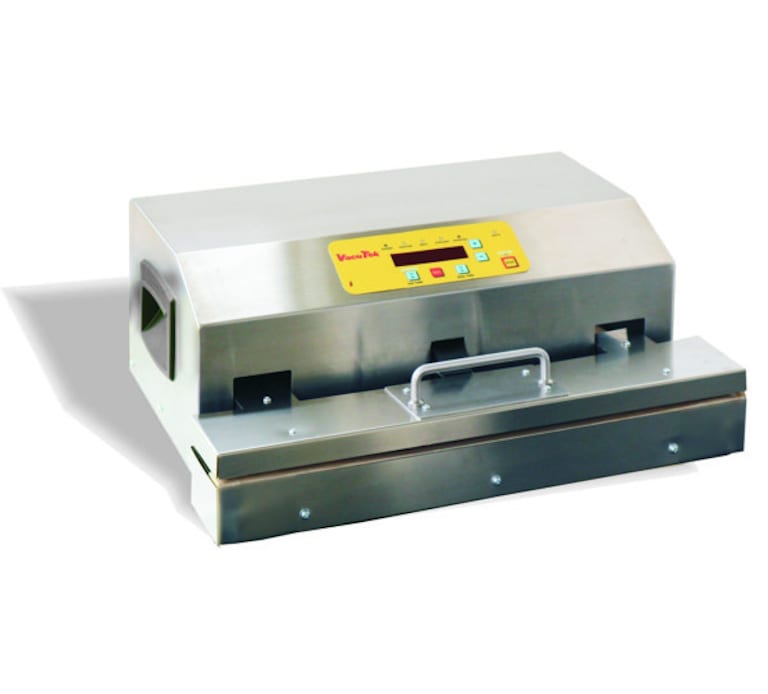

A Vacuum Heat Sealer can then be used during this process to remove excess air with a desiccant added to ensure any remaining moisture in the air is absorbed. Using a HIC (Humidity Indicator Card) placed inside the bag will then confirm the maximum relative humidity level on opening.

We offer a full range of MBB (Moisture Barrier Bags) for use with packaging and resealing MSDs (Moisture Sensitive Devices). These tough bags ensure that once sealed no moisture can travel through the material over time and allow safe storage and transportation of devices.

Copyright 2012 – 2019 LINK HAMSON | All Rights Reserved | Powered by DIG Online