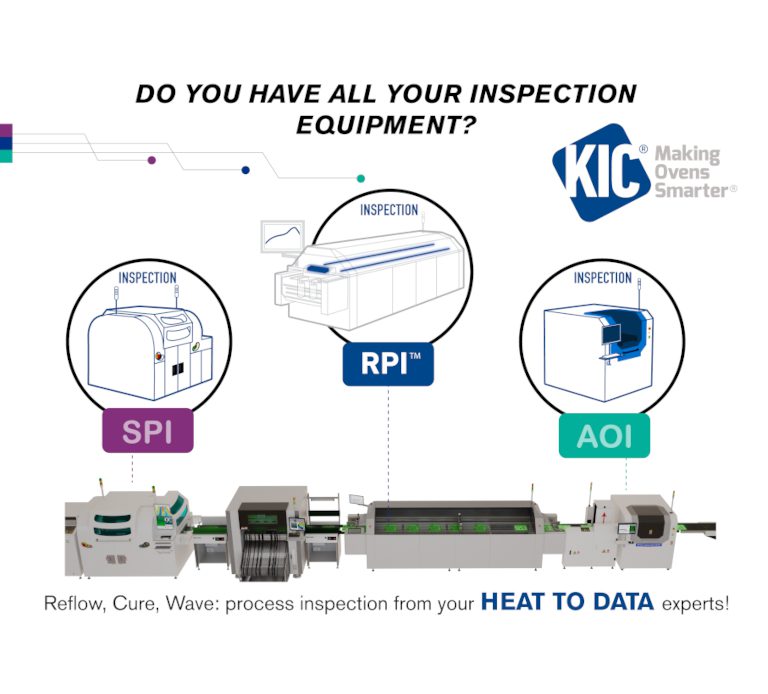

Completes the assembly line ‘Inspection’ data, providing all the live critical reflow data in a way that SPI does for solder paste & AOI does for component placement.

FULL Traceability for all your production.

A Full Reflow Profile for EVERY board produced, AUTOMATICALLY

Traceability and Process Data for each PCB processed – Meets Auditors requirements…automatically

Meet requirements for medical devices for ISO 13485

Reflow Quality, Yield and Defect Monitoring – Combine your RPI data with SPI and AOI data for a complete answer!

Improved Reflow Process Quality reduces defects, downtime and saves money

SMEMA control of in-feed, to instantly stop boards when the process is out of spec…or if the wrong recipe is loaded!

SPC & Cpk chart feature for monitoring process drift over time and production batch changes

Live Management Data – for MES / CEM systems

Barcode Software for Traceability and Process Control (only allows ‘matched’ products in to the oven).

Data can be linked to KIC Vantage Factory, a factory level Industry 4.0 smart factory system for reflow and cure data management and analytics

"*" indicates required fields

Copyright 2012 – 2019 LINK HAMSON | All Rights Reserved | Powered by DIG Online